Advantage

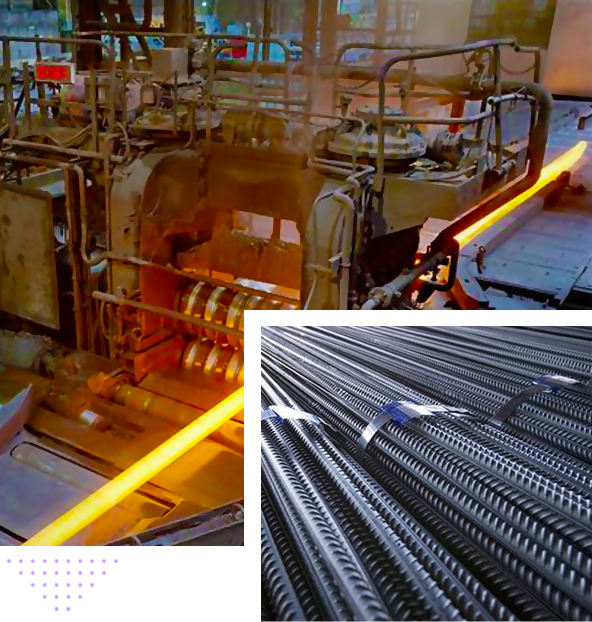

Advantage Of Gemini TMT

The process used ensures combination of tempered martensite on the surface ad fine grain ferrite-pearilite in the core providing higher strength, toughness and ductility.

Gemini TMT Bars are produced in straight length. After passing through the cooling system Gemini TMT is passed through a Special Rotary Flying Shear which ensures perfect straightness.

TMT Bars can be bent on mandrels easily as per BIS specification which is due to hard outer surface and soft inner core results with excellent value of bendability in Gemini TMT Bars.

Gemini TMT bars show virtually no rusting even after a long time, as there is absence of residual stress. Appropriate Chemistry, Micro-structure ensures high level of resistance in corrosive atmosphere. A true friend for cement to prevent corrosion.

The alloy chemistry and process parameters are controlled to achieve a high stress ratio (UTS/YS) at high level of ductility enabling the steel bar to absorb higher in-elastic strain energy during cyclic loading encountered in earthquake condition.

No loss of strength even at high temperature of 600°C leading to better security of concrete structure.

Distinctly superior to normal TMT bars, GEMINI TMT Fe 500/ Fe 500D/ Fe 550 bars ensure a reduction of upto approximate 18% in steel usage while providing the same strength.

Project Links

Project Links

-

Mobile No.

7073081982, 9414061704 -

Phone No.

+(91)-(141)-2460998, +(91)-(141)-4048565 -

Email id

[email protected]

[email protected] -

Address

Gemini Steel Limited F-947,48,49, E-292 Road No.14, Vishwakarma Industrial Area Jaipur - 302013